ABOUT US

ABOUT MASIA MINES S.A

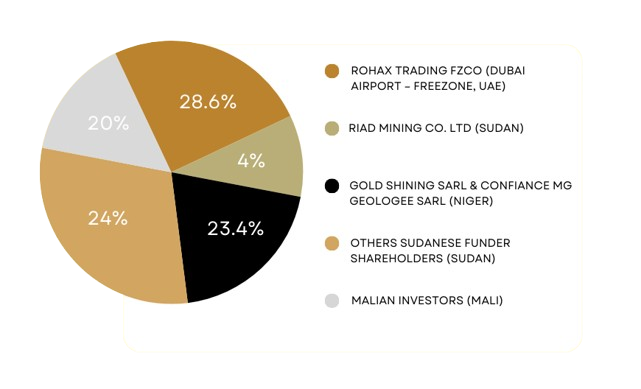

MASIA MINES S.A has been Founded since 2020 in Mali, owned by a Sudanese Experts in minng & joint venture of many company (Gold Shining SARL & CONFIANCE MG GEOLOGEE SARL, Riad Mining Co.,Ltd, ROHAX TRADING FZCO, Malian Investors), and ever since we have been consistently thriving and working toward excellence in mining sector. And through Mali expanded new branch has been Founded since 2021 in Guinea Conakry,

We have stablished two site works, first one in Gbonko Area-Mandiana province for treatment artisanal miners waste tailing for residue gold & Industrial waste such fine carbon, And second site in Morignoumala Area-Kouroussa province.

We have been executed more than 8+ project, by capital Capex 14+ million USD.

By different types of processes & extraction gold, such as (Heap leach, VAT leach & CIL) using extraction techniques such as (Merrill Crowe system & CIC).

OUR SUBSIDIARIES

MASIA MINES S.A partners also Riad Mining Co.,Ltd which has been founded since 2015, the Government of the Republic of Sudan – Ministry of Minerals Federal granted Experiment an license to work in the field of waste treatment artisanal mining for gold (Al-Karta) in the River Nile State, as first company to entry & used the Ore Dressing Agent “JinChan” in Sudan for replacement of sodium cyanide, and specializing in the industrial field used the Ore Dressing Agent, and won the privilege of working in the field of waste (Al-Karta) by safety & Environment friendly way.

In 2016, Ministry of Minerals Federal of Sudan was agreed to give our partner company (Riad Mining) final license to work in the field of waste treatment artisanal mining for gold (Al-Karta) & industrial (fine carbon) after succeed Technically experiment of the replacement Sodium cyanide (Ore Dressing Agent) till now.

Also our partner Gold Shining SARL & CONFIANCE MG GEOLOGEE SARL in Niger, which has been founded since 2015, Started by established Wet Pan Mills Complex for ASM service to accumulated waste tailing as first stage plan in Um Zikr Site located Eastern-Northern of City center Niamey, Nearly Agadez City (about E 150 km), Despite facing many challenges and difficulties, such as (poor infrastructure, poor availability of basic requirements for tools and equipment, the absence of a port that impeded the deportation process, the rareness of technical labor, etc.), However the project was continued within the strategic plan & has been got license for Small Scall Mine & also treatment Artisanal Miners tailing for extract remining gold.

OUR GOALS

The Objectives of MASIA MINES aims at making the best benefit of land source with high quality & less cost using the best human resources, natural resources, knowledge and high technology, to practice different mining activities as well as developing mining manufacture and mining productions the related manufactures. It also aims at cleaning the environmental using advancement tools. The company aims at providing the staff with good working environment. And to achieve the objectives, the company applies the standard international quality and property measurements, providing all the required aids such as choosing the qualified cadres, modern technology, training and developing, communication devices, and machines, etc.

OUR VISION

Our vision to establish a strong mining company and build a high-level factory that can produce gold from the traditional mining detritus, to share our own knowledge experiences which was bossed for many years in Sudan & Niger countries by Best Available Techniques “BAT” & Best environmental practices ”BEP”.

OUR MISSION

“Maximizing wealth through sustainable mining activities”

Our mission is working together to provide sustainability, stability, prosperity and health care through stable leverage of Mining turning natural resources into capital and sustainable development that will enable partners to achieve their opportunities for growth

OUR MESSAGE

Our massage is to use the human capacities, mineral resources, and applying the modern technology to reach a highly qualified productivity, and to reduce the level of environmental pollution that is caused by the ASM sector’s.

OUR VALUE

“Human First is our core value for all of our activities.”

Our purpose is always putting the Human First, to bring their needs along with available resources to make the world an eternally better place.

PRINCIPLES

Carefully implementing the policies that comprehensive planning, properly scheduling, turning harm into good, environmental friendly, benefiting the people, and insisting the principles that primarily prevention, combining prevention with control, integrated management. Be active to utilize advanced techniques and equipment's, increase the utilization rate of resource and energy, in order to achieve the optimal economic benefit and environmental benefit after the project put into operation.

PROCESSING TECHNOLOGY

We use Merrill-Crowe process system for extracting Gold from leaching solution, Zinc dust cementation for gold recovery is one of the best known contact reducing processes in mineral processing. It is also known as Merrill-Crowe process from its founders, C.W Merrill of United States of America who started it and T.B Crowe from South Africa who added some important developments (Miller, 1981). Merrill-Crowe process is used for gold precipitation from dilute sodium cyanide solutions or Ore Dressing Agent “JinChan” and is favoured for gold cyanide containing high silver concentration. The Tailing is leached before going through zinc precipitation. After zinc-dust cementation, the processed gold is taken for smelting. started it and T.B Crowe from South Africa who added some important developments (Miller, 1981). Merrill-Crowe process is used for gold precipitation from dilute sodium cyanide solutions or Ore Dressing Agent “JinChan” and is favoured for gold cyanide containing high silver concentration. The Tailing is leached before going through zinc precipitation. After zinc-dust cementation, the processed gold is taken for smelting.

LEADERSHIP TEAM

Our leadership team is comprised of seasoned professionals with extensive experience in mining industry “specialized in Waste treatment Fine Carbon & Artisanal Tailing”.

Their expertise and strategic vision drive MASIA MINES S.A towards continued growth and innovation, through experience have possess & accumulated over generations starting with RIDA GROUP.

OWNERSHIP

- Capacity: 50 Kt yearly artisanal tailing “6 ~ 12 Au g/t”. & 5 Kt fine Carbon.

- Processing: Heap & Vat Leach. Extraction

- Process: Merrill Crowe System.

Capacity: 70 Kt yearly artisanal tailing “3 ~ 5 Au g/t”.

Processing: Vat Leach & Small-Scale CIL.

Extraction Process: Merrill Crowe System & CIC .

- Establishment: February 2014

- Provides supply chain services for mining raw materials (procurement and logistics) including :

1. Mining and Equipment Tr

2. Gold Chemicals Trading.

3. Industrial Chemicals Trading.

4. Construction Chemicals Trading.

5. Laboratories Chemicals Trading.

Capacity: 80 Kt yearly artisanal tailing “3 ~ 5 Au g/t”.

Processing: Vat Leach.

Extraction Process: Merrill Crowe System.